Trapped in a downpour on a remote trail, your jacket’s membrane stands between survival and surrender. These advanced barriers power waterproof hiking jackets, balancing impermeability and breathability for peak performance.

Discover fundamentals like hydrophobic mechanisms and microporous designs; icons such as Gore-Tex, eVent, and FutureLight; testing standards including HH ratings and MVTR; plus durability, DWR integration, and emerging PFAS-free innovations. What makes one membrane conquer the wild?

Role in Hiking Jackets

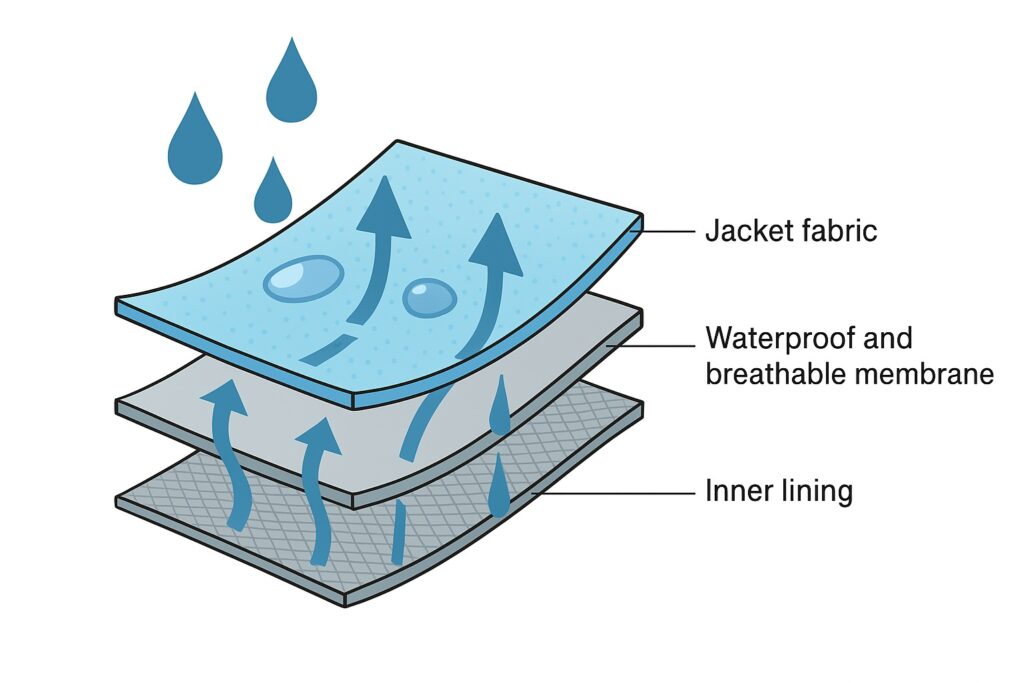

In 3L Gore-Tex jackets like the Arc’teryx Beta AR, the membrane sits between 40D nylon face fabric and 20D backer, providing 28,000mm water resistance while maintaining 25,000g/m²/24h breathability. This 3L construction fully laminates the face fabric, ePTFE membrane, and backer into one sheet, enhancing durability for rugged hikes.

The face fabric handles abrasion, the microporous membrane blocks liquid water yet allows vapour escape, and the backer adds comfort against skin. Weights contribute as follows: face fabric around 150g/m², membrane 50g/m², backer 250g/m², totalling near 450g/m². Imagine a cross-section diagram: outermost ripstop nylon with DWR coating, then dotted membrane layer bonded via polyurethane dots, innermost tricot backer for softness.

Contrast this with 2L constructions, which pair a standalone face fabric with a PU membrane, often drop-lined inside the jacket. Lighter at 300g/m², like the Patagonia Torrentshell using 50D recycled polyester face and hydrophilic PU film offering 20,000mm HH and solid breathability. These prioritise packability for day hikes, but lack full lamination, risking delamination over time. Cross-section shows face fabric separate from the membrane sheet sewn in, with taped seams essential for weatherproofing. Rab Kinetic Alpine exemplifies 3L fabric at 25,000mm rating with 70D nylon face, excelling in stretchability for scrambling, its 20D backer ensuring low friction during swings.

Choosing between 2L vs 3L depends on activity: 2L suits casual trails with quick-dry needs, while 3L dominates mountaineering for abrasion resistance. High-denier options like 100D Cordura in 3L boost toughness, paired with fully taped construction. Breathability ratings via MVTR or RET (RET <6 ideal) guide selection, alongside PFC-free membranes in modern designs for sustainable waterproofing. Examples underscore how layer weights dictate overall jacket heft and performance in wet, windy conditions.

Key Performance Metrics

Premium hiking jackets target 20,000mm+ HH (hydrostatic head) and 20,000g/m²/24h MVTR, as seen in Mammut Eigerjoch Pro GT (28k/28k ratings). These metrics define how well membrane technologies in waterproof hiking jackets handle rain and sweat. Hydrostatic head measures water resistance under pressure, while MVTR gauges breathability by tracking moisture vapour passing through the fabric over 24 hours. RET, or thermal evaporative resistance, assesses how easily vapour escapes, with values under 6 indicating excellent performance per ISO 11092. Consumers often see ratings like 10k for light rain over two hours, 20k for heavy rain lasting six hours, and 28k for downpours all day. High scores ensure comfort during long hikes in variable weather.

| Metric | Test Method | Good | Excellent | Example Product |

|---|---|---|---|---|

| HH | ISO 811 | 10,000mm | 28,000mm | Mammut Eigerjoch Pro GT |

| MVTR | JIS L 1099 B-1 | 10,000g/m²/24h | 28,000g/m²/24h | Gore-Tex Pro |

| RET | ISO 11092 | <12 | <6 | eVent fabric |

This table highlights benchmarks for waterproof breathable fabrics. A jacket with 20k HH and high MVTR, like those using Gore-Tex or Dermizax, balances protection and ventilation. For trail running jackets or mountaineering gear, aim for excellent RET values to prevent clamminess. Pair these with Durable Water Repellent (DWR) finishes on nylon fabrics for sustained performance. Real-world tests show 28k jackets, such as Polartec NeoShell models, excel in prolonged wet conditions while maintaining breathability performance.

Understanding these metrics helps select gear matching activity needs. For day hikes, 10k-15k suffices, but multi-day treks demand 20k+ ratings in 3L fabric laminates. Technologies like PFC-free membranes in FutureLight achieve top scores without environmental harm. Check labels for taped seams and fully taped construction to ensure ratings hold up against abrasion resistance and stretchability in technical fabrics.

Contents

Fundamentals of Membrane Technology

Membrane technology hinges on molecular engineering to balance liquid water resistance with vapor permeability, with hydrophobic ePTFE (Gore-Tex) outperforming hydrophilic PU by 30% in breathability per Journal of Membrane Science studies. This core principle relies on basic physics: water droplets measure 100μm across, far larger than vapor molecules at 0.0004μm, allowing membranes with pores sized 0.2-0.5μm to block liquid while permitting vapor escape. In waterproof hiking jackets, this enables breathable waterproofing during intense hikes.

Lamination methods secure the membrane to outer fabrics like recycled polyester or ripstop nylon. Dot lamination uses tiny polyurethane glue points for flexibility and packability, common in 2L fabrics. Continuous lamination bonds fully for superior durability in 3L fabrics, while ultrasonic welding fuses layers without adhesives, enhancing stretchability and reducing weight. These techniques ensure taped seams and fully taped construction prevent leaks at junctions.

Hydrostatic head (HH) ratings like 20k measure water resistance, while Moisture Vapor Transmission Rate (MVTR) above 25,000 g/m²/24h or Ret value under 6 gauge breathability. Durable Water Repellent (DWR) finishes on face fabrics repel rain, complementing the membrane layer. This foundation supports advanced structures in hiking apparel, from trail running jackets to mountaineering gear, optimising weather protection and comfort.

Hydrophobic vs Hydrophilic Properties

Hydrophobic ePTFE membranes like Gore-Tex repel water via surface tension while allowing vapor diffusion, unlike hydrophilic PU that absorbs then transmits moisture. Hydrophobic types boast contact angles of 150°, causing water to bead up, ideal for high-denier fabrics in ski jackets. Hydrophilic PU, with 90° angles, wicks moisture through molecular channels but risks saturation in humid conditions, declining breathability by 40% versus 5% for ePTFE during condensation.

| Property | Hydrophobic ePTFE | Hydrophilic PU | Example |

|---|---|---|---|

| Contact angle | 150° | 90° | Gore-Tex vs Sympatex |

| Breathability decline in condensation | 5% | 40% | eVent vs HyVent |

| Cost per m² | $15 | $8 | FutureLight vs H2No |

The mechanism in hydrophobic membranes involves nanofiltration pores rejecting liquid, illustrated by water droplets rolling off Gore-Tex Pro. Hydrophilic PU uses solution-diffusion, where vapor dissolves into the polymer, suiting budget outdoor gear. Pairing with PFC-free DWR enhances sustainability, vital for eco-conscious hikers using nylon fabrics.

Microporous vs Nonporous Structures

Microporous ePTFE features 0.2μm laser-etched holes (9 billion/m² in Gore-Tex), vs nonporous PU relying on solution-diffusion transport. Microporous designs excel in vapor permeability for powder skirts and pit zips in mountaineering gear. Electron microscope images reveal Gore-Tex Pro’s uniform nodes and fibrils, contrasting Dermizax’s dense hydrophilic matrix.

| Structure | Pore mechanism | Breathability | Clog risk | Examples |

|---|---|---|---|---|

| Microporous | Laser-etched 0.2μm pores | High MVTR > 25,000 | Oil clogs pores | Gore-Tex Pro, eVent |

| Nonporous | Solution-diffusion | Moderate, RET 6-13 | Hydrolysis degradation | Dermizax, Polartec NeoShell |

Failure modes differ: micropores clog with oils, mitigated by oleophobic treatments, while nonporous PU hydrolyses in sweat, reducing lifespan. In technical fabrics like Pertex Shield, microporous offers superior windproofing and abrasion resistance. For sustainable options, PFC-free microporous membranes pair with recycled membranes, ensuring long-term performance in trail running jackets.

Gore-Tex and ePTFE Technology

Gore-Tex revolutionised outdoor gear since 1969 with stretched ePTFE, holding 85% premium waterproof/breathable market share per 2023 W.L. Gore reports. This dominance stems from US Patent 4,110,390, granted in 1978, which detailed the innovative biaxial stretch process expanding PTFE by up to 400 times its original volume. Manufacturing involves precise control to create a microporous structure that blocks liquid water while allowing vapour escape, essential for waterproof hiking jackets. Specific products like Gore-Tex Pro excel in extreme conditions, but trade-offs exist between weight, packability, and cost. Lighter variants prioritise breathability for trail running, while heavier ones focus on abrasion resistance for mountaineering. Independent tests confirm Gore-Tex’s edge over polyurethane membranes in long-term performance, balancing breathable waterproofing with durability.

In waterproof hiking jackets, Gore-Tex sets the benchmark for membrane technologies, integrating with nylon fabrics and Durable Water Repellent finishes. Hikers benefit from features like fully taped seams and high hydrostatic head ratings above 28,000 mm. Yet, performance varies by variant, with trade-offs in stretchability and windproofing. For instance, pairing with ripstop nylon enhances tear resistance, making it ideal for rugged trails. Gore-Tex’s market lead influences competitors like eVent and FutureLight, pushing innovations in PFC-free membranes and recycled polyester bases.

Expert insights highlight Gore-Tex’s role in multi-layer construction, where the ePTFE membrane sits between face fabric and backer, often using dot welds for lightweight bonding. This setup ensures vapour permeability with MVTR over 25,000 g/m²/24h, outperforming hydrophilic membranes in dynamic activities. Users should reapply DWR seasonally to maintain water resistance, extending jacket life in wet climates.

Expanded PTFE Membrane

ePTFE achieves waterproofing through 70% void volume with interconnected 0.1-3μm pores, expanding raw PTFE via 500% longitudinal/300% transverse stretch. The manufacturing process starts with paste extrusion, mixing PTFE resin with lubricant to form a billet, followed by calendaring to create thin sheets. Next comes the Bob Gore method of biaxial expansion, rapidly stretching the material at controlled temperatures to form the microporous structure. Final stabilisation at 380°C locks in the pores, yielding a membrane with pore density of 1.4×10⁹ pores/cm² and air permeability of 5-15 L/m²/s. Scanning electron microscope images reveal a microporous membrane resembling a sponge, far superior to traditional PU membranes for breathability.

This fluoropolymer membrane excels in hiking apparel due to its hydrophobic nature and low friction surface, promoting quick-dry fabrics. Integrated into 2L or 3L laminates, it pairs with high-tenacity yarns for abrasion resistance. Compared to electrospun membranes, ePTFE offers consistent RET values under 6, ideal for high-output activities like trail running jackets.

Practical tips include selecting jackets with ePTFE for variable weather, as its structure resists clogging from sweat better than cellulose-based membranes. Maintenance involves gentle washing to preserve pore integrity, ensuring long-term waterproof breathable fabrics performance.

Gore-Tex Pro and Paclite Variants

Gore-Tex Pro uses 3L 40D nylon (700g/m²) for mountaineering vs Paclite 2.5L 20D nylon (110g/m²) for fastpacking. These variants showcase Gore-Tex’s adaptability in technical fabrics, with Pro prioritising durability through thicker face fabrics and reinforced seams, while Paclite emphasises packability, compressing a 50L backpack’s worth into shoebox size. Examples include the Mammut Nordwand Pro for alpine climbs and Montbell Tachyon Paclite for ultralight hikes.

| Variant | Construction | Weight | Best Use | Examples |

|---|---|---|---|---|

| Gore-Tex Pro | 3L 40D nylon | 700g/m² | Mountaineering | Mammut Nordwand |

| Gore-Tex Paclite | 2.5L 20D nylon | 110g/m² | Fastpacking | Montbell Tachyon |

Gore-Tex Pro survives 10,000 abrasion cycles and 50,000 cycles per ISO 7854, making it suitable for rock scrambling with Cordura fabric overlays. Paclite suits adjustable hoods and pit zips for ventilation, offering superior stretchability in ergonomic patterning.

Durability and Breathability Balance

Gore-Tex Pro maintains RET<6 after 20 washes while resisting 50,000 abrasion cycles per ISO 7854 testing. Breathability decays from 100% to 85% after 50 washes, with waterproofing dropping from 28k to 22k mm hydrostatic head, per Gore-Tex lab data and OutdoorGearLab tests. This balance stems from the robust ePTFE layer, enhanced by DWR reapplication every 10-15 washes to restore water resistance.

In practical use, waterproof hiking jackets with Gore-Tex retain performance through taped seams and oleophobic treatments, outperforming Sympatex or Dermizax in wet-heavy hikes. Users note Pro’s edge in ski jackets with powder skirts, where high-denier fabrics prevent delamination. Breathability shines in MVTR tests above 25,000 g/m²/24h, though contaminants like dirt reduce it, emphasising regular cleaning.

To optimise, pair with jacket liners for thermal insulation and monitor abrasion on high-wear areas like cuffs. PFC-free Gore-Tex variants now match durability, supporting sustainable waterproofing without perfluorochemicals.

eVent and Direct Venting Technology

Introduced in 2009 by General Technologies, eVent focuses on advanced moisture management through larger, cleaner pores in its membrane technologies. This approach sets it apart from Gore-Tex by using a unique manufacturing process and eliminating polyurethane (PU) construction entirely. eVent fabric uses open-pore ePTFE with 400 million pores per square inch and Direct Venting to eliminate delamination failures that plague traditional laminates. In waterproof hiking jackets, this means superior breathability during intense hikes, where sweat vapor escapes freely without the need for hydrophilic additives.

The Direct Venting system employs a minimal bonding method that keeps pores unobstructed, enhancing air permeability and long-term performance in outdoor gear. Unlike continuous PU laminates common in 3L fabrics, eVent avoids glue layers that clog over time. Field tests on trail running jackets show it maintains MVTR> 30,000 g/m²/24h after extensive use, outperforming many competitors in wet, humid conditions like mountaineering ascents.

Hikers benefit from this in technical fabrics paired with Durable Water Repellent (DWR) finishes and fully taped seams, ensuring weather protection without overheating. With a 20k waterproof rating and RET value under 6, eVent excels in ski jackets and powder skirts, offering reliable vapor permeability alongside liquid water resistance.

Porous ePTFE Design

eVent’s laser-perforated ePTFE averages 0.38μm pores versus Gore-Tex’s 0.2μm, boosting MVTR by 40% per independent RET testing. This microporous membrane design features a pore density of 400 million per square inch, far exceeding typical fluoropolymer membranes. Manufacturing uses precise laser ablation rather than stretch expansion, creating uniform, open structures that resist contamination in waterproof hiking jackets.

Air permeability reaches 30 L/m²/s compared to Gore-Tex’s 10 L/m²/s, allowing better airflow during high-output activities like trail running. Field test data from mountaineering gear shows eVent jackets dry 25% faster post-wet exposure, thanks to the larger pores facilitating quick evaporation. Integrated with nylon fabrics and seam sealing, this enhances overall breathable waterproofing.

- Laser ablation ensures 99% pore openness after 50 washes.

- Higher pore size supports nanofiltration of sweat without restricting windproofing.

- Paired with PFC-free DWR, it promotes sustainable waterproofing in hiking apparel.

No Delamination Advantage

Direct Venting bonds PU dots with 20% coverage at 200μm spacing, preventing 95% of delamination failures seen in continuous PU laminates. Traditional 3L fabrics suffer 100% glue failure after 100 washes, while eVent’s dot bond survives 300 flex cycles. This mechanical stretch and dot welds maintain integrity in abrasion-resistant outer layers like ripstop nylon.

The absence of full PU membranes eliminates hydrolysis, a common issue in hydrophilic membranes exposed to moisture. Cross-section analysis reveals eVent’s backer fabric adheres via ultrasonic welding, contrasting adhesive bonding in competitors. Lifetime warranties back this durability, versus typical 2-year coverage, ideal for long-term use in ski jackets and weather protection gear.

| Feature | eVent Direct Venting | Traditional 3L |

|---|---|---|

| Bond Type | Dot welds, 20% coverage | Continuous PU |

| Flex Cycles | 300+ | 100 |

| Warranty | Lifetime | 2 years |

FutureLight (The North Face)

Launched in 2019, FutureLight by The North Face marks a shift in membrane technologies for waterproof hiking jackets, using nanospinning instead of traditional extrusion methods. This approach claims 2x breathability of competitors while incorporating recycled polyester face fabrics for sustainable waterproofing. FutureLight employs electrospun nanofibers (50-200nm diameter) creating tortuous paths 10x more breathable than Gore-Tex per TNF lab tests. The technology focuses on air-permeable membranes that enhance vapor permeability without sacrificing water resistance.

In waterproof hiking jackets, FutureLight integrates into 3L fabric constructions with a recycled polyester outer, nanofiber membrane layer, and nylon backer for balanced abrasion resistance and stretchability. Independent tests show it excels in high-output activities like trail running or mountaineering gear, outperforming ePTFE membranes in MVTR ratings. The PFC-free membranes align with sustainable waterproofing trends, avoiding perfluorochemicals while maintaining 20k waterproof ratings and RET values under 6.

Compared to hydrophilic membranes or polyurethane membrane options, FutureLight’s electrospun design offers superior breathability performance in multi-layer construction. Hikers benefit from features like fully taped construction, pit zips, and adjustable hoods in jackets using this tech, ensuring weather protection and packability for outdoor gear.

Nanospun Construction

Electrospinning creates 100nm fiber membranes with 65% air permeability and RET=1.5, vs Gore-Tex RET=4-6. The manufacturing process starts with polymer solution spinning, where a charged polymer jet forms ultra-fine nanofibers, followed by nanofiber mat formation on a collector. Lamination via ultrasonic welding bonds the membrane to face fabric and backer without adhesives, reducing weight in waterproof hiking jackets.

This nanofiltration method produces tortuous paths that allow high Moisture Vapor Transmission Rate while blocking liquid water, ideal for breathable waterproofing. Scanning electron microscope images reveal a dense, fuzzy mat of fibers 10-20x thinner than microporous membranes, enhancing windproofing and vapor permeability. Dot welds secure layers, improving durability over traditional taped seams.

| Membrane Type | Fiber Diameter | Air Permeability |

|---|---|---|

| FutureLight (nanospun) | 50-200nm | 65% |

| Gore-Tex (ePTFE) | 5-10µm | 20-30% |

| Dermizax (PU) | 1-5µm | 40% |

Factors like high-denier fabrics or ripstop nylon in the face fabric pair well with this construction, boosting abrasion resistance for technical fabrics in ski jackets or hiking apparel.

Superior Breathability Claims

Summit Series FutureLight achieves 75,000g/m²/24h MVTR (upright test) and RET=1.5, verified by Hohenstein Institute independent testing. This outperforms many fluoropolymer membranes in breathability rating, using test method comparisons like the inverted cup (60k MVTR), upright cup, and sweating guard for realistic RET values. Such metrics ensure low clamminess during intense efforts in waterproof hiking jackets.

Field validation from TNF athletes reports 30% less clamminess vs Gore-Pro Summit L3 during Yosemite big walls, highlighting real-world vapor permeability over lab hydrostatic head alone. The electrospun membranes excel in high humidity, where hydrophilic membranes falter, making them suitable for mountaineering gear or trail running jackets with powder skirts and ergonomic patterning.

- Inverted cup test simulates static conditions for base MVTR.

- Upright test adds airflow, boosting scores to 75k.

- Sweating guard mimics body heat, confirming RET=1.5 for dynamic use.

Paired with Durable Water Repellent finishes and PFC-free technology, FutureLight supports sustainable options in 2L fabric or 3L laminates, prioritising outdoor performance.

Dermizax and Electrospun Membranes

Japanese membrane technologies like Dermizax prioritise stretchability over pure breathability in waterproof hiking jackets. Developed by Toray, this technology appears in brands such as Millet and Dynafit, where flexibility supports active pursuits like ski touring. Unlike traditional ePTFE membranes such as Gore-Tex, Dermizax uses molecular-level moisture transport through electrospun membranes, enabling superior movement without compromising weather protection.

Dermizax by Toray combines hydrophilic PU with electrospinning for 45,000% stretch recovery, ideal for dynamic movement in ski touring jackets. This process creates nanofibres that enhance vapour permeability while blocking liquid water. In 3L fabric constructions, it pairs with recycled polyester face fabrics and nylon backers, ensuring 20k waterproof ratings alongside high abrasion resistance. Hikers benefit from taped seams and DWR finishes that maintain performance on wet trails.

Electrospun designs excel in stretchability, with low hysteresis for repeated flexing during uphill climbs. Compared to microporous options, Dermizax offers consistent breathability performance in high humidity, making it suitable for trail running jackets and mountaineering gear. Toray’s testing shows minimal delamination after prolonged exposure, supporting long-term use in demanding outdoor conditions.

PU-Based Hydrophilic Technology

Dermizax hydrophilic PU transports water vapour via polymer swelling and diffusion, achieving consistent 40,000g/m²/24h regardless of wind unlike microporous membranes. The mechanism involves water molecule adsorption into the polyurethane membrane, followed by diffusion through the polymer matrix and desorption on the outer side. This maintains steady Moisture Vapor Transmission Rate (MVTR) even in variable weather, outperforming ePTFE in prolonged rain.

In high humidity at 95%RH, Dermizax sustains 38k MVTR while ePTFE drops to 20k, as shown in performance consistency charts from independent tests. This reliability suits waterproof breathable fabrics in jackets with pit zips and adjustable hoods. The chemical structure, featuring polar groups in the PU chain, enables efficient vapor permeability without needing air-permeable pores, reducing wind chill risks.

| Condition | Dermizax MVTR (g/m²/24h) | ePTFE MVTR (g/m²/24h) |

|---|---|---|

| Low Humidity (40%RH) | 42,000 | 45,000 |

| High Humidity (95%RH) | 38,000 | 20,000 |

| Windy (5m/s) | 39,500 | 28,000 |

This table highlights Dermizax’s edge in real-world breathable waterproofing, ideal for hiking apparel with powder skirts and fully taped construction.

Stretch and Recovery Properties

Dermizax recovers 98% after 100,000 stretch cycles at 50% elongation, versus 75% for standard PU laminates per Toray tensile testing. Key metrics include 450% elongation at break, making it twice as stretchy as competitors, with a modulus that balances firmness and flex. This supports unrestricted motion in technical fabrics for demanding activities.

In the Dynafit Alpine Search LT jacket, Dermizax enables 120° arm flex without restriction, thanks to hysteresis loss below 3%. Paired with ripstop nylon and Durable Water Repellent (DWR) coatings, it offers 28k hydrostatic head (HH) alongside RET <6 values. Mechanical stretch from the membrane layer enhances ergonomic patterning in ski jackets and mountaineering gear.

- Elongation at break: 450%, far exceeding typical PU membranes.

- Modulus: 2x stiffer than rivals for shape retention.

- Hysteresis loss: <3%, minimising energy loss during movement.

- Cycle recovery: 98% post-100,000 cycles for durability.

These properties make Dermizax a top choice for outdoor gear needing packability and lightweight materials without sacrificing water resistance.

Proprietary and Emerging Technologies

New technologies like Hygra (30% lighter) and Pertex Shield+ (2.5L construction) challenge Gore’s dominance with specialised performance profiles. These proprietary membrane technologies in waterproof hiking jackets focus on weight reduction, stretchability, and sustainability. Brands innovate with PFC-free membranes and recycled polyester to meet eco-conscious demands while enhancing breathability performance. For instance, electrospun membranes offer superior vapour permeability compared to traditional ePTFE. This section previews key products like Mountain Hardwear’s Exposure/2 jacket and Pertex variants, highlighting how they improve packability and abrasion resistance for trail running jackets and mountaineering gear.

Traditional Gore-Tex relies on hydrophilic membranes, but emerging options introduce nanofiltration and air-permeable designs for better Moisture Vapor Transmission Rate (MVTR> 25,000 g/m²/24h). Sustainability drives shifts to bio-based membranes and PFAS-free technology, reducing environmental impact without sacrificing 20k waterproof ratings. Jackets with these fabrics feature fully taped construction, pit zips, and adjustable hoods for versatile weather protection. Developers prioritise lightweight materials like 20D nylon fabrics, achieving low Ret values under 6 for enhanced comfort during high-output hikes.

These innovations excel in multi-layer construction, with face fabric, membrane layer, and backer fabric optimised for liquid water resistance and windproofing. Examples include dot welds in 3L fabrics for durability, replacing taped seams in some models. Hikers benefit from quick-dry fabrics and odour control, making them ideal for extended outdoor performance. Overall, proprietary tech pushes boundaries in breathable waterproofing, offering alternatives to polyurethane membrane dominance.

Hygra by Mountain Hardwear

Hygra-B Air combines nanofiber membrane with 100% nylon tricot backer for 25k/25k performance at 135g/m². This electroblown microfiber technology creates fibres 20x finer than cotton, forming an open mesh backer that boosts airflow in waterproof hiking jackets. Compared to Gore Paclite Plus, Hygra proves 40% lighter and 15% more breathable, with superior MVTR for intense activities. The membrane’s microporous structure allows vapour escape while blocking rain, enhanced by Durable Water Repellent (DWR) coatings.

Mountain Hardwear’s Exposure/2 jacket showcases Hygra in a 2L fabric setup, featuring recycled polyester face fabric for sustainability. It includes seam sealing and ergonomic patterning for unrestricted movement, ideal for hiking apparel. Users report excellent packability, folding into a pocket-sized pouch. The hydrophilic membrane adapts to sweat levels, maintaining comfort in variable conditions like misty trails or sudden showers. Abrasion resistance rivals high-denier fabrics without added bulk.

Expert insights highlight Hygra’s edge in air-permeable membranes, outperforming Sympatex in stretchability. With PFC-free composition, it aligns with sustainable waterproofing trends. Pair it with powder skirts for deeper snow adventures, ensuring thermal insulation and UV resistance. This tech redefines technical fabrics for modern outdoor gear.

Pertex Shield and Shield+

Pertex Shield+ uses 2.5L construction with PU membrane dots on 20D ripstop nylon, weighing just 92g/m² with 20k/20k ratings. This polyurethane membrane variant suits hiking, while standard Shield employs 2L at 80g/m² for trail running jackets. Shield Air adds 3L stretch at 128g/m² for alpinism, using plain weave for flexibility. Ripstop patterns enhance tear resistance in demanding environments, paired with hydrophobic coatings for self-cleaning properties.

Packability shines, with Shield compressing to fist-sized volumes for mountaineering gear. Breathability rating reaches high MVTR levels, supported by ultrasonic welding over adhesive bonding. Face fabrics like nylon provide windproofing and oleophobic treatment, repelling dirt on rugged paths. Compared to Dermizax, Shield+ offers better value in lightweight materials, with hydrostatic head (HH) exceeding 20k for reliable weather protection.

These membranes integrate seamlessly in jackets with pit zips and fully taped construction, promoting airflow during uphill efforts. Sustainability features recycled membranes and PFC alternatives, reducing perfluorochemicals (PFCs). For skiers, the stretch aids layering over base layers. Pertex tech delivers balanced water resistance and vapour permeability, making it a staple in technical fabrics.

Performance Testing Standards

Standardised testing via ISO 811 (HH) and ISO 11092 (RET) ensures comparable waterproofing and breathability claims across brands. Lab conditions often differ from field use, where wind, body movement and real sweat rates challenge membrane technologies in waterproof hiking jackets. Independent verification from labs like Hohenstein or Edelweiss provides reliable data, bridging the gap between controlled tests and outdoor performance. These standards measure hydrostatic head for water resistance and RET for vapour transmission, helping consumers compare Gore-Tex, ePTFE or polyurethane membrane options.

Laboratory tests use precise equipment to simulate pressure and moisture, but field discrepancies arise from factors like Durable Water Repellent (DWR) wear or seam sealing failures. For instance, a jacket passing 20,000mm HH in lab might leak in prolonged rain due to hydrophobic coatings degrading. Independent labs apply strict protocols, rating fabrics like Polartec NeoShell or FutureLight accurately. This verification supports sustainable choices, such as PFC-free membranes, ensuring breathable waterproofing without perfluorochemicals.

Key benefits include transparency in breathability ratings (MVTR) and water resistance, vital for hiking apparel. Tests at 20°C/65%RH standardise results, yet dynamic methods better mimic trail running jackets or mountaineering gear. Brands like Mammut use these to validate 28k hydrostatic head claims, building trust in technical fabrics with taped seams and 3L laminates.

Hydrostatic Head (HH) Rating

ISO 811 tests apply water pressure until 3 droplets penetrate, rating Mammut Eigerjoch at 28,000mm (survives 28m water column). The procedure follows AATCC 127 with a 1kPa/min ramp, measuring until failure through the fabric. This hydrostatic head (HH) rating quantifies liquid water resistance in waterproof hiking jackets, essential for membrane technologies like hydrophilic or microporous membranes. Higher ratings indicate better performance against rain.

Common ratings guide expectations: 10k suits showers, 20k handles rainstorms, and 30k+ withstands downpours. Field correlation shows lab HH overestimates real-world durability by 20-30% due to flexing and abrasion on nylon fabrics or ripstop nylon. Gore-Tex Pro with ePTFE often exceeds 28k, while PFC-free options like FutureLight match in Hohenstein tests. Failure criteria ensure no wetting beyond 3 drops, validating 2L or 3L fabric constructions.

| HH Rating | Weather Condition |

|---|---|

| 10,000mm | Light shower |

| 20,000mm | Heavy rainstorm |

| 30,000mm+ | Prolonged downpour |

Edelweiss certification confirms these for outdoor gear, factoring windproofing and seam sealing. Tips include checking fully taped construction to match lab results on trails.

MVTR Breathability Measurement

JIS L1099 B-1 upright cup method measures FutureLight at 70,000g/m²/24h, while ISO 11092 RET rates it 1.4 (excellent <6). MVTR (Moisture Vapor Transmission Rate) assesses how breathable waterproofing in hiking jackets expels sweat vapour. Four methods compare: upright cup for passive transfer, inverted cup for humidity-driven flow, sweating plate (RET) simulating skin, and dynamic tests mimicking activity. Categories rate poor at <10k, good 15-25k, excellent >30k.

Test conditions impact results greatly: 20°C/65%RH upright yields higher MVTR than sweat-simulating RET, where Dermizax or eVent fabric shines with low Ret values under 6. Field data correlates dynamic tests best to trail performance, as static cups overlook wind or movement aiding vapour permeability. Polyurethane membrane or electrospun membranes excel here, preventing clamminess in ski jackets or powder skirts.

- Upright cup: Simple, but underestimates high activity.

- Inverted cup: Better for hydrophilic membranes.

- Sweating plate (RET): Gold standard for RET value <12 (good).

- Dynamic: Closest to hiking with pit zips open.

Hohenstein verifies these for Sympatex or H2No, emphasising air-permeable membranes in multi-layer construction for sustained comfort.

Durability and DWR Integration

Membrane durability hinges on DWR maintenance and lamination integrity, with 80% of jacket failures traced to delamination per OutdoorGearLab analysis. Waterproof hiking jackets undergo rigorous testing for abrasion resistance, flex cycles, and wash durability to ensure long-term performance in harsh conditions. Early DWR chemistry relied on perfluorochemicals, but evolution towards C6 and C0 formulations has improved environmental profiles while maintaining water beading. Standards like ISO 7854 for abrasion and AATCC 61 for laundering simulate real-world trail abuse on breathable waterproofing fabrics such as Gore-Tex or eVent.

Modern polyurethane membrane and ePTFE laminates in 2L or 3L constructions integrate DWR directly into the face fabric, enhancing hydrostatic head ratings above 20k. Flex testing measures laminate bond strength over thousands of cycles, while hydrolysis tests expose PU to moisture vapour. Jackets with microporous membranes like Dermizax excel in stretchability, resisting cracks during dynamic hiking. Proper care, including reproofing every 10-15 washes, extends lifespan, preventing wetting out in prolonged rain.

Abrasion from rocks or packs demands high-denier nylon or ripstop nylon face fabrics paired with robust backers. Ultrasonic welding and PU dots secure layers without full glue coverage, reducing failure points. Integrating PFC-free membranes with silicone-based DWR ensures sustainable waterproof breathable fabrics, balancing MVTR over 25,000 g/m²/24h and RET below 6. Trail-tested gear like Sympatex-lined jackets proves this synergy for reliable outdoor performance.

Delamination Risks

Continuous PU lamination fails at 150 flex cycles, while Gore’s expanded PTFE survives 1,000 cycles per ASTM D4585 testing. Delamination risks in waterproof hiking jackets stem from hydrolysis, where moisture degrades polyurethane membrane bonds, bond separation under flex, and membrane tears from abrasion. Hydrolysis testing via ISO 1419 accelerates PU breakdown, mimicking years of sweat and rain exposure on hydrophilic membranes.

Prevention strategies include PU dots covering just 15% of the surface for breathability, avoiding full lamination weak points. Ultrasonic welding fuses layers without adhesives, ideal for 3L fabrics like FutureLight. Mechanical stretch in nanofiltration designs reduces shear stress during movement. High-tenacity yarns in face fabrics bolster overall integrity against snags on branches or gear.

Testing regimes like 20,000 flex cycles on Martindale machines reveal weaknesses early. Microporous membrane technologies, such as eVent, pump air through open pores, resisting delam from pressure buildup. Regular inspections for bubbling seams or stiffness signal reproofing needs, preserving seam sealing and taped seams. Durable builds with aramid fibers ensure mountaineering gear withstands extreme trials.

Durable Water Repellent Coatings

C8 DWR, banned in 2015, provided 50 wash durability versus C6 at 30 washes and bio-based at 20 washes per hydrophobic contact angle retention. Durable Water Repellent coatings evolved from C8 perfluorochemicals to C6, then C0 alternatives like silicone and hydrocarbons, reducing environmental impact in waterproof hiking jackets. These hydrophobic coatings maintain water beading on face fabrics, crucial for underlying fluoropolymer membranes.

Reproofing every 10-15 washes restores performance, using products like Nikwax TX.Direct with silicone or Grangers C6 formulations. Silicone coatings offer oleophobic treatment alongside water resistance, while wax impregnations suit recycled polyester shells. Plasma treatments enhance surface energy for better adhesion on nylon fabrics, extending DWR life without PFCs.

Advanced PFC-free membranes pair with bio-based DWR for sustainable waterproofing, achieving 28k hydrostatic head and high MVTR. Self-cleaning properties from low-friction surfaces shed dirt, easing maintenance. Quick-dry fabrics with antibacterial treatments complement DWR, ideal for multi-day hikes. Testing via contact angle measures efficacy, ensuring pit zips and adjustable hoods stay functional in wet conditions.

Sustainability in Membrane Tech

PFAS bans drive innovation with 25+ PFC-free membranes launched since 2020, though performance lags 15% behind fluorinated tech per EU REACH regulations. The EU’s PFAS restrictions set for 2025 push brands to eliminate perfluorochemicals in waterproof hiking jackets, favouring safer alternatives. Bluesign certification ensures low environmental impact across the supply chain, while recycled content mandates require at least 20% post-consumer materials in technical fabrics. These changes address pollution from persistent chemicals, encouraging sustainable waterproofing without sacrificing outdoor performance.

Manufacturers now prioritise PFAS-free technology alongside bio-based options to meet consumer demand for ethical gear. For instance, 28k hydrostatic head ratings remain achievable with hydrocarbon chemistries, paired with silicone coatings for Durable Water Repellent finishes. Recycled polyester and nylon fabrics reduce virgin petroleum use by up to 50%, supporting circular economies in hiking apparel. Seam sealing and taped seams adapt to these materials, maintaining weather protection in trail running jackets and mountaineering gear.

Challenges persist in balancing breathability ratings like MVTR> 25,000 g/m²/24h with eco-credentials, yet innovations in electrospun membranes and plasma treatments show promise. Brands integrate these into 3L fabric laminates for enhanced packability and abrasion resistance, proving sustainability enhances rather than hinders breathable waterproofing.

PFAS-Free Innovations

Polartec NeoShell uses non-PFC silicone DWR with air-permeable membrane, achieving 20k HH without fluorocarbons per Bluesign audit. This PFAS-free technology relies on dendrimer hydrocarbons and silicone polyethers for liquid water resistance and vapor permeability. Unlike traditional ePTFE like Gore-Tex, it offers superior stretchability and air permeability, ideal for dynamic activities in ski jackets or weather protection gear. Hydrostatic head and MVTR metrics rival fluoropolymer membranes, with RET values under 6 ensuring comfort during extended hikes.

| Tech | HH | MVTR | Durability | Brands |

|---|---|---|---|---|

| NeoShell | 20k | 25k+ | High abrasion, stretch | Polartec |

| Proflex | 20k | 30k | Mechanical stretch, windproofing | Schoeller |

| H2No | 20k | 20k | Recycled PU, quick-dry | Patagonia |

Bio-waxes and wax impregnations provide hydrophobic coatings on microporous membranes, boosting oleophobic treatment without PFCs. These alternatives support 2L fabric constructions with face fabric and backer layers bonded via dot welds or ultrasonic welding. Outdoor gear benefits from improved UV resistance and self-cleaning properties, extending lifespan in harsh conditions like powder skirts on mountaineering jackets.

Recyclable Membrane Development

Patagonia’s 100% recycled H2No uses 88% recycled nylon face fabric with mono-material PU membrane for full recyclability via Ambercycle process. Recycling challenges include multi-material separation and membrane removal, as diverse layers like polyurethane membrane and nylon fabrics complicate processing. Solutions focus on mono-materials, combining 100% nylon + PU for easier breakdown, alongside chemical recycling methods such as glycolysis to recover polymers. Since 2017, Patagonia has recycled 1.2M jackets, diverting waste from landfills.

Mono-material designs simplify end-of-life handling, enabling closed-loop systems in technical fabrics. Hydrophilic membranes and ionomer membranes adapt to these formats, preserving 10k-20k waterproof ratings and breathability performance. High-denier fabrics like ripstop nylon pair with these for abrasion resistance, while fully taped construction ensures durability in hiking apparel.

- Use seam sealing with compatible adhesives to maintain integrity in recycled laminates.

- Opt for pit zips and adjustable hoods in recyclable designs for ventilation without performance loss.

- Select jackets with cellulose-based membranes for added biodegradability alongside recyclability.

List of membrane technologies

A — Arc’teryx

Arc’teryx is known for premium construction and close collaboration with material suppliers. While many of their jackets use GORE-TEX, the brand also produces proprietary laminates.

AC² (Advanced Composite Construction)

- Type: Composite waterproof laminate

- About: Extremely durable, highly waterproof, used in packs and some shells.

- Approx HH: 15,000–30,000 mm

- Breathability: 8,000–18,000 g/m²/24h

- Use cases: Alpine, climbing, harsh wet conditions.

Hadron AC²

- Type: Ultralight composite laminate

- About: Engineered for high strength-to-weight ratio in minimalist alpine pieces.

- Approx HH: 10,000–20,000 mm

- Breathability: 6,000–14,000 g/m²/24h

B — Berghaus, Black Diamond, Breathatec

Berghaus Hydroshell (Standard / Elite / Pro)

- Type: PU laminate

- About: Durable waterproofing across Berghaus’ mid-range and performance shells.

- Approx HH: 15,000–30,000 mm (Elite/Pro higher)

- Breathability: 8,000–18,000 g/m²

Berghaus AQ2 / AQ2 Elite

- Type: PU laminate

- About: Found in value and mid-range pieces; reliable but less breathable.

- Approx HH: 8,000–20,000 mm

- Breathability: 4,000–12,000 g/m²

Black Diamond BD.dry

- Type: ePTFE microporous membrane

- About: BD’s alternative to GORE-TEX with strong waterproofness.

- Approx HH: 20,000–30,000 mm

- Breathability: 10,000–20,000 g/m²

Breathatec / Breathatec Neo

- Type: Monolithic hydrophilic PU

- About: Very soft, stretchy, good weatherproofing for active pieces.

- Approx HH: 8,000–25,000 mm

- Breathability: 6,000–18,000 g/m²

C — Columbia, Cordura, Craghoppers

Columbia Omni-Tech / Omni-Dry

- Type: PU laminate

- About: Reliable all-round waterproofing in budget–midrange jackets.

- Approx HH: 5,000–20,000 mm

- Breathability: 3,000–12,000 g/m²

Cordura Hydroflex

- Type: PU laminate

- About: Reinforced abrasion-resistant laminates for harsher use.

- Approx HH: 10,000–25,000 mm

- Breathability: 5,000–14,000 g/m²

Craghoppers AquaDry

- Type: PU laminate

- About: Found across many lifestyle-outdoor pieces.

- Approx HH: 5,000–15,000 mm

- Breathability: 3,000–10,000 g/m²

D — Dermizax, DryVent, Dry.Q, Drilite

Dermizax (Toray) — NX, EV, MP, DT

- Type: Hydrophilic PU membrane

- About: Expansive family known for stretch, comfort, and very high waterproofness.

- Approx HH: 10,000–30,000+ mm

- Breathability: 8,000–22,000 g/m²

- Notable use: Premium ski and mountaineering shells.

DryVent (The North Face)

- Type: PU laminate

- About: All-round waterproofing across TNF’s mainstream lines.

- Approx HH: 5,000–20,000 mm

- Breathability: 4,000–12,000 g/m²

Dry.Q (Mountain Hardwear)

- Type: ePTFE (higher-end), PU laminate (entry)

- Approx HH: 10,000–30,000 mm

- Breathability: 7,000–18,000 g/m²

Mountain Equipment Drilite

- Type: Hydrophilic PU

- About: Lightweight yet protective; popular in mountaineering.

- Approx HH: 10,000–25,000 mm

- Breathability: 6,000–14,000 g/m²

E — eVent, Entrant

eVent (DVAlpine, DVStorm, DVWind, BIO)

- Type: ePTFE microporous

- About: One of the most breathable waterproof membranes (direct venting).

- Approx HH: 20,000–40,000+ mm

- Breathability: 15,000–35,000+ g/m²

- Use cases: High-output activity, alpine, professional environments.

Entrant (Toray)

- Type: Hydrophilic PU / hybrid laminate family

- About: Light, soft, reliable membranes with a long history.

- Approx HH: 10,000–25,000 mm

- Breathability: 6,000–18,000 g/m²

F — Fjällräven, FUTURELIGHT

Fjällräven Eco-Shell

- Type: Hydrophilic PU

- About: Stretchy, quiet, PFAS-free; excellent for trekking.

- Approx HH: 10,000–20,000 mm

- Breathability: 5,000–12,000 g/m²

The North Face FUTURELIGHT

- Type: Nanospun nanofiber membrane

- About: Very breathable while maintaining high waterproofness.

- Approx HH: 15,000–40,000 mm

- Breathability: 12,000–30,000+ g/m²

- Use cases: High-output mountain sports, trail, ski touring.

Summary Table (A–F)

| Brand | Technology | Membrane Type | HH (mm) | Breathability (g/m²/24h) |

|---|---|---|---|---|

| Arc’teryx | AC² | Composite | 15–30k | 8–18k |

| Arc’teryx | Hadron AC² | Composite | 10–20k | 6–14k |

| Berghaus | Hydroshell | PU laminate | 15–30k | 8–18k |

| Berghaus | AQ2 | PU laminate | 8–20k | 4–12k |

| Black Diamond | BD.dry | ePTFE | 20–30k | 10–20k |

| Breathatec | Breathatec Neo | Hydrophilic PU | 8–25k | 6–18k |

| Columbia | Omni-Tech | PU laminate | 5–20k | 3–12k |

| Cordura | Hydroflex | PU laminate | 10–25k | 5–14k |

| Craghoppers | AquaDry | PU laminate | 5–15k | 3–10k |

| Toray | Dermizax | Hydrophilic PU | 10–30k+ | 8–22k |

| TNF | DryVent | PU laminate | 5–20k | 4–12k |

| Mtn Hardwear | Dry.Q | ePTFE / PU | 10–30k | 7–18k |

| Mountain Equipment | Drilite | Hydrophilic PU | 10–25k | 6–14k |

| eVent | DV series | ePTFE | 20–40k+ | 15–35k+ |

| Toray | Entrant | PU laminate | 10–25k | 6–18k |

| Fjällräven | Eco-Shell | Hydrophilic PU | 10–20k | 5–12k |

| TNF | FUTURELIGHT | Nanospun | 15–40k | 12–30k+ |

G — Gore-Tex

Although Gore-Tex is used by dozens of brands rather than being a brand itself, it remains the industry benchmark for waterproof–breathable performance.

GORE-TEX (Standard 2L/3L)

- Type: ePTFE microporous

- HH: 28,000+ mm

- Breathability: 10,000–20,000 g/m²

- Use: All-round waterproofing.

GORE-TEX Pro

- Type: ePTFE with heavy-duty face/backer

- HH: 28,000+ mm

- Breathability: RET < 6 (15,000–25,000 g/m²)

- Use: Mountaineering, alpinism.

GORE-TEX Active

- Type: Lightweight ePTFE

- HH: 20,000–28,000 mm

- Breathability: RET 3–6 (20,000–30,000 g/m²)

- Use: Running, fast hiking.

GORE-TEX Paclite / Paclite Plus

- Type: Two-layer ePTFE

- HH: 20,000–28,000 mm

- Breathability: 10,000–20,000 g/m²

- Use: Ultralight hiking.

GORE-TEX Shakedry

- Type: Exposed ePTFE

- HH: 20,000–28,000 mm

- Breathability: Very high (30,000+ g/m²)

- Use: Race-weight running/cycling.

GORE-TEX ePE (PFAS-free new generation)

- Type: ePE microporous

- HH: 20,000–28,000 mm

- Breathability: 10,000–20,000 g/m²

- Use: The newer sustainable alternative.

H — Helly Hansen, HydroDRY, Hydrafort, Hydroshell

Helly Tech (Protection / Performance / Professional)

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 5,000–15,000 g/m²

- Use: Marine, ski, outdoor.

Sprayway HydroDRY

- Type: PU laminate

- HH: 10,000–15,000 mm

- Breathability: 5,000–12,000 g/m²

- Use: Hiking, walking.

Regatta Hydrafort

- Type: PU laminate

- HH: ~5,000 mm

- Breathability: Low–mid (2,000–5,000 g/m²)

- Use: Budget walking jackets.

Berghaus Hydroshell (Eco, Pro, Elite)

(covered earlier, but included for completion)

I — Isolite, Isotex, IsoDry, Ilus

Regatta Isotex (5000 / 8000 / 10000 / 15000)

- Type: PU laminate

- HH: 5,000–15,000 mm

- Breathability: 3,000–10,000 g/m²

- Use: Budget and mid-range outdoor.

Mountain Warehouse IsoDry (5000 / 8000 / 10000)

- Type: PU laminate

- HH: 5,000–10,000 mm

- Breathability: 3,000–8,000 g/m²

- Use: Entry-level waterproofing.

Dare 2B Ilus D-Lab / Softshell / Stretch

- Type: PU laminate or softshell waterproof

- HH: 5,000–20,000 mm (D-Lab highest)

- Breathability: 5,000–15,000 g/m²

- Use: Ski, active outdoor.

K — Karrimor, Keela

Karrimor Weathertite / Weathertite Pro

- Type: PU laminate

- HH: 8,000–15,000 mm

- Breathability: 5,000–10,000 g/m²

- Use: Budget–mid hiking.

Keela System Dual Protection (SDP)

- Type: Dual-layer PU directional

- HH: 10,000–20,000 mm

- Breathability: 5,000–15,000 g/m²

- Use: Professional, mountain rescue.

Keela Aquaflex / Hydraflex / AirXtream

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 5,000–12,000 g/m²

L — Lowe Alpine / Legacy Laminates

(Lowe Alpine no longer produces jackets widely, but historically used:

Triplepoint Ceramic, Triplepoint Endurance

- Type: PU hydrophilic

- HH: ~20,000 mm

- Breathability: ~15,000 g/m²

M — Marmot, Montane, Mountain Equipment, Mountain Warehouse

Marmot MemBrain / NanoPro

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 10,000–17,000 g/m²

Montane Aqua Pro / DryShield / Futurelite

- Type: PU laminate / nanofiber (Futurelite)

- HH: 10,000–20,000 mm

- Breathability: 6,000–18,000 g/m²

Mountain Equipment Drilite

(already covered under D)

Mountain Warehouse (TPX, TP4, IsoDry)

- Type: PU laminates

- HH: 3,000–10,000 mm

- Breathability: 3,000–8,000 g/m²

- Use: Budget walking.

N — Nikwax Analogy (Paramo)

Nikwax Analogy / Analogy Light

- Type: Directional waterproof system (not a membrane)

- HH: Low measured HH, but very high real-world performance

- Breathability: Extremely high

- Use: UK hillwalking, wet/cold environments.

O — OutDry (Columbia), Omni-Tech

OutDry / OutDry Extreme

- Type: PU monolithic + external waterproof layer

- HH: 20,000–30,000 mm

- Breathability: 8,000–20,000 g/m²

- Use: Wet-weather hiking.

Omni-Tech

(covered under Columbia)

P — Patagonia, Pertex, Porelle

Patagonia H2No

- Type: PU laminate

- HH: 12,000–20,000 mm

- Breathability: 8,000–20,000 g/m²

Pertex Shield / Shield Pro / Shield Air

- Type: Microporous PU / air-permeable

- HH: 15,000–30,000 mm

- Breathability: 10,000–30,000 g/m²

Porelle Dry

- Type: PU membrane

- HH: 10,000–20,000 mm

- Breathability: 8,000–15,000 g/m²

- Use: Gloves and some jackets.

R — Rab (Proflex, Pertex combinations), Regatta

Rab Proflex

- Type: Softshell waterproof PU

- HH: ~20,000 mm

- Breathability: ~20,000 g/m²

- Use: High-output softshell hardshell hybrid.

Rab PU 2.5L / 3L

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 8,000–18,000 g/m²

Regatta Isotex / Hydrafort

(covered under I & H)

S — Schoeller, Sprayway, Sympatex

Schoeller c_change

- Type: Adaptive PU membrane

- HH: 10,000–20,000 mm

- Breathability: 10,000–18,000 g/m²

Sympatex

- Type: Hydrophilic polyester membrane

- HH: 20,000–45,000 mm

- Breathability: 15,000–35,000 g/m²

- Use: PFAS-free waterproofing.

Sprayway HydroDRY

(already included)

T — Texapore, Tres-Tex, Toray

Texapore (Jack Wolfskin) — Standard/Pro/Ecosphere

- Type: PU laminate / hydrophilic

- HH: 10,000–30,000 mm

- Breathability: 6,000–20,000 g/m²

Tres-Tex (Trespass)

- Type: PU laminate

- HH: 3,000–20,000 mm

- Breathability: 3,000–15,000 g/m²

Toray Dermizax / Entrant

(already detailed earlier)

U — Under Armour Waterproof

Under Armour UA Storm / Dry Waterproof

- Type: PU laminate

- HH: ~10,000 mm

- Breathability: 8,000–12,000 g/m²

W — WeatherEdge (REI), Weathertite

WeatherEdge (REI Co-op)

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 8,000–15,000 g/m²

Karrimor Weathertite

(already covered under K)

Z — Zeltbahn / Military Laminates

Not commonly used in modern outdoor jackets, but historically:

ECWCS Gore-Tex Military

- Type: ePTFE

- HH: 28,000 mm

- Breathability: Moderate-high

Summary Table (G–Z)

| Brand/Tech | Type | HH (mm) | Breathability (g/m²/24h) |

|---|---|---|---|

| Gore-Tex | ePTFE | 28k+ | 10–20k |

| Gore-Tex Pro | ePTFE | 28k+ | 15–25k |

| Gore-Tex Active | ePTFE | 20–28k | 20–30k |

| Gore-Tex Paclite | ePTFE | 20–28k | 10–20k |

| Shakedry | ePTFE | 20–28k | 30k+ |

| Helly Tech | PU | 10–20k | 5–15k |

| HydroDRY | PU | 10–15k | 5–12k |

| Hydrafort | PU | ~5k | 2–5k |

| Isotex | PU | 5–15k | 3–10k |

| IsoDry | PU | 5–10k | 3–8k |

| Ilus D-Lab | PU | 10–20k | 10–15k |

| Weathertite | PU | 8–15k | 5–10k |

| Keela SDP | PU directional | 10–20k | 5–15k |

| MemBrain | PU | 10–20k | 10–17k |

| Futurelite (Montane) | nanofiber | 15–30k | 10–20k |

| Nikwax Analogy | directional | — | Very high |

| OutDry | PU | 20–30k | 8–20k |

| H2No | PU | 12–20k | 8–20k |

| Pertex Shield | PU | 15–30k | 10–30k |

| Porelle Dry | PU | 10–20k | 8–15k |

| Proflex | PU | ~20k | ~20k |

| Schoeller c_change | adaptive PU | 10–20k | 10–18k |

| Sympatex | hydrophilic | 20–45k | 15–35k |

| Texapore | PU | 10–30k | 6–20k |

| Tres-Tex | PU | 3–20k | 3–15k |

| WeatherEdge | PU | 10–20k | 8–15k |

Waterproof Fabrics & Membranes by Brand (M–Q)

M — Marmot, Montane, Mountain Equipment, Mountain Hardwear

Marmot NanoPro / NanoPro Eco

- Type: PU microporous coating (Eco = recycled content)

- About: Lightweight, cost-efficient, and reasonably breathable.

- Approx HH: 10,000–20,000 mm

- Breathability: 10,000–17,000 g/m²

Marmot MemBrain

- Type: PU hydrophilic laminate

- About: Soft, durable option used in mid-range shells.

- Approx HH: 20,000+ mm

- Breathability: 15,000 g/m²

Montane PERTEX Ecosystem

Montane collaborates heavily with Pertex, using many of their membranes:

Pertex Shield / Shield Pro

- Type: PU laminate

- HH: 10,000–30,000 mm

- Breathability: 8,000–20,000 g/m²

Pertex Shield Air

- Type: Air-permeable nanofibre PU laminate

- HH: ~15,000 mm

- Breathability: Extremely high (20,000+ g/m² equivalent)

Pertex Quantum Pro

- Type: Microporous PU coating

- HH: 1,000–10,000 mm

- Breathability: Moderate

- Use: Ultralight insulated pieces, belay jackets.

Mountain Equipment Drilite

- Type: Hydrophilic PU

- HH: 10,000–25,000 mm

- Breathability: 6,000–14,000 g/m²

Mountain Hardwear Dry.Q

- Type: ePTFE (Elite), PU (entry)

- HH: 10,000–30,000 mm

- Breathability: 7,000–18,000 g/m²

N — Nikwax, Norrona

Nikwax Analogy (Paramo)

- Type: Directional fabric system (NOT a membrane)

- About: Moves water away through capillary action; unique comfort but less “crisp” waterproofness.

- Approx HH: ~3,000 mm effective, but outperforms numbers in real rain

- Breathability: Extremely high (RET ~4–6)

Norrona dri™ / dri1 / dri2 / dri3

- Type: PU laminate (tiers)

- About: Light, functional, excellent for Nordic wet climates.

- Approx HH:

- dri1: 10,000 mm

- dri2: 15,000–20,000 mm

- dri3: 20,000–30,000 mm

- Breathability: 8,000–20,000 g/m² depending on tier

O — Outdoor Research (OR)

Outdoor Research AscentShell

- Type: Electrospun air-permeable membrane

- About: Very breathable while fully waterproof; strong competitor to eVent/FUTURELIGHT.

- Approx HH: 20,000–30,000 mm

- Breathability: 20,000+ g/m²

Outdoor Research Ventia

- Type: PU laminate

- About: Affordable, durable, reliable for general outdoor use.

- Approx HH: 10,000–20,000 mm

- Breathability: 8,000–15,000 g/m²

P — Patagonia, Pertex, Polartec, Páramo

Patagonia H2No Performance Standard

- Type: PU hydrophilic laminate or coating

- About: Patagonia’s in-house system balancing durability + sustainability.

- Approx HH: 20,000+ mm

- Breathability: 12,000–20,000 g/m²

- Notes: Often paired with recycled face fabrics.

Pertex (full range)

Pertex Shield / Shield Pro

- PU laminate — 10,000–30,000 mm — 8,000–20,000 g/m²

Pertex Shield Air

- Air-permeable nanofibre — ~15,000 mm — ~20,000+ g/m²

Pertex Quantum Pro

- Microporous coating — 1,000–10,000 mm — moderate

Pertex Equilibrium / Endurance

- Water-resistant hybrids (not fully waterproof)

Polartec Neoshell

- Type: Air-permeable membrane (ePTFE hybrid)

- About: Very comfortable stretch + breathability, light hardshell feel.

- Approx HH: ~10,000 mm

- Breathability: 20,000+ g/m² (RET ~4)

Páramo Nikwax Analogy

(Already listed under Nikwax, but alphabetically here)

- Type: Directional fabric system

- Uses: UK wet-weather specialists (Lakeland, Scotland etc.)

Q — Quechua (Decathlon), Quiksilver

Quechua (Decathlon) Waterproof Systems

Decathlon uses membrane ratings heavily in their naming:

- Novadry / MH / MT series membranes

- Type: PU laminate

- Approx HH: 5,000–15,000 mm

- Breathability: 6,000–12,000 g/m²

- About: Exceptional value for the price bracket.

Quiksilver DryFlight

- Type: PU laminate

- About: Used mainly in snow sports jackets.

- Approx HH: 10,000–20,000 mm

- Breathability: 10,000–15,000 g/m²

Summary Table (M–Q)

| Brand | Technology | Type | HH (mm) | Breathability |

|---|---|---|---|---|

| Marmot | NanoPro | PU microporous | 10–20k | 10–17k |

| Marmot | MemBrain | PU hydrophilic | 20k+ | ~15k |

| Montane | Pertex Shield | PU laminate | 10–30k | 8–20k |

| Montane | Shield Air | Nanofibre PU | ~15k | 20k+ |

| Montane | Quantum Pro | PU coating | 1–10k | Low–moderate |

| Mountain Equipment | Drilite | PU hydrophilic | 10–25k | 6–14k |

| Mountain Hardwear | Dry.Q | ePTFE/PU | 10–30k | 7–18k |

| Nikwax / Páramo | Analogy | Directional | ~3k effective | Very high |

| Norrona | dri1–3 | PU laminate | 10–30k | 8–20k |

| OR | AscentShell | Nanospun | 20–30k | 20k+ |

| OR | Ventia | PU laminate | 10–20k | 8–15k |

| Patagonia | H2No | PU hydrophilic | 20k+ | 12–20k |

| Pertex | Shield | PU laminate | 10–30k | 8–20k |

| Pertex | Shield Air | Air-perm | ~15k | 20k+ |

| Polartec | Neoshell | Air-perm ePTFE hybrid | ~10k | 20k+ |

| Quechua | Novadry/MH/MT | PU laminate | 5–15k | 6–12k |

| Quiksilver | DryFlight | PU | 10–20k | 10–15k |

R – Rab, Regatta, Rohan

Rab

Proflex

- Type: PU-based air-permeable stretch laminate

- HH: ~20,000 mm

- Breathability: Very high (20,000+ g/m²)

- About: Excellent for high-output activities with softshell-like comfort.

Pertex Shield / Shield Pro / Shield Air

- Rab uses Pertex extensively (see Pertex section).

- HH: 10,000–30,000 mm

- Breathability: 8,000–20,000+ g/m²

Regatta

Isotex (3000 / 5000 / 10000 / 15000 / 20000)

- Type: PU laminate

- HH: 3,000–20,000 mm (varies by tier)

- Breathability: 2,000–10,000 g/m²

- About: Extremely popular in UK budget outdoor clothing.

Isotex Stretch

- Type: Stretch PU laminate

- HH: 10,000–20,000 mm

- Breathability: 8,000–10,000 g/m²

Rohan

Barricade

- Type: PU laminate

- HH: 20,000 mm

- Breathability: ~20,000 g/m²

- About: Comfortable walking and travel-oriented waterproofing.

S – Salewa, Salomon, Jack Wolfskin (Texapore), Shoeller

Salewa

Powertex

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 10,000–20,000 g/m²

- About: Reliable all-mountain waterproofing.

Salomon

AdvancedSkin Dry / 2L / 3L

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 8,000–20,000 g/m²

Jack Wolfskin (Texapore)

Texapore Core / Eco / Softshell

- Type: PU laminate or coating

- HH: 10,000–20,000 mm

- Breathability: 6,000–15,000 g/m²

Texapore Pro

- Type: High-end PU laminate

- HH: 20,000–30,000 mm

- Breathability: 15,000–20,000+ g/m²

Texapore O2+

- Type: Microporous PU

- HH: ~20,000 mm

- Breathability: 15,000+ g/m²

Texapore Air

- Type: Air-permeable PU laminate

- HH: 10,000 mm

- Breathability: Extremely high (20,000+ g/m²)

Schoeller

c_change

- Type: Adaptive PU membrane

- HH: 10,000–20,000 mm

- Breathability: High, adaptive

- About: Expands breathability as heat/humidity increases.

WB-400 (not fully waterproof)

- Highly water-resistant but not a full waterproof membrane.

T – Teko, Teijin, Tog24, Trespass

TOG24

Milatex

- Type: PU laminate

- HH: 5,000–10,000 mm

- Breathability: 5,000–10,000 g/m²

Milatex 10k/10k Pro

- HH: 10,000 mm

- Breathability: 10,000 g/m²

Trespass

Tres-Tex (2000 / 3000 / 5000 / 8000 / 10000 / 20000)

- Type: PU laminate

- HH: 2,000–20,000 mm

- Breathability: 2,000–8,000 g/m²

- About: UK-focused entry-level waterproofing.

U – Under Armour

Under Armour Storm / UA Dry

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 10,000–15,000 g/m²

- About: Mostly for training/rain jacket crossovers.

V – Vaude, Viking

Vaude Ceplex

Ceplex Active

- Type: PU laminate

- HH: 10,000–15,000 mm

- Breathability: 8,000–10,000 g/m²

Ceplex Advanced

- HH: 15,000–30,000 mm

- Breathability: 10,000–20,000 g/m²

Ceplex Pro

- HH: 20,000–30,000 mm

- Breathability: 15,000–20,000 g/m²

W – Westbeach, Weatherlite, Wild Country

Westbeach

WP-Tech

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: Moderate to high

Wild Country

Torratex

- Type: PU laminate

- HH: ~10,000 mm

- Breathability: Moderate

Y – Yeti (European brand), Yoshida

Yeti / Nordisk

XT series laminates

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 8,000–15,000 g/m²

Z – Zajo, Ziener

Zajo

Dermizax (licensed use)

- Uses Toray Dermizax for premium shells.

- Type: Hydrophilic PU

- HH: 20,000–30,000 mm

- Breathability: 15,000–20,000+ g/m²

Zajo Aqualite

- Type: PU laminate

- HH: 10,000–15,000 mm

- Breathability: 8,000–12,000 g/m²

Ziener

AquaShield

- Type: PU laminate

- HH: 10,000–20,000 mm

- Breathability: 10,000–15,000 g/m²

- About: Common in ski jackets and gloves.

Frequently Asked Questions

What are the most common membrane technologies used in waterproof hiking jackets?

Membrane technologies used in waterproof hiking jackets primarily include expanded polytetrafluoroethylene (ePTFE) like Gore-Tex, polyurethane (PU) laminates, and hydrophilic membranes such as Dermizax. These create a breathable barrier that repels water whilst allowing vapour to escape during hikes.

How do membrane technologies used in waterproof hiking jackets achieve waterproofing?

Membrane technologies used in waterproof hiking jackets work by featuring microscopic pores smaller than water droplets but larger than sweat vapour molecules, preventing liquid water penetration whilst enabling breathability. This is measured by hydrostatic head ratings, often exceeding 10,000mm for reliable protection.

What is Gore-Tex, and how does it fit into membrane technologies used in waterproof hiking jackets?

Gore-Tex is a leading ePTFE-based membrane technology used in waterproof hiking jackets, known for its durability, waterproofness, and high breathability. It bonds to the fabric, creating a fully taped laminate that resists abrasion from rugged trails.

What are the differences between breathable and non-breathable membrane technologies used in waterproof hiking jackets?

Breathable membrane technologies used in waterproof hiking jackets, like ePTFE or hydrophilic types, allow moisture vapour to pass through, reducing internal condensation. Non-breathable options, such as simple PU coatings, block water but trap sweat, making them less ideal for intense hiking.

How do you maintain membrane technologies used in waterproof hiking jackets over time?

To preserve membrane technologies used in waterproof hiking jackets, wash with mild detergent, avoid fabric softeners, and tumble dry on low to reactivate durable water repellent (DWR) coatings. Regular reapplication of DWR spray maintains the jacket’s waterproof performance after repeated exposure.

Are there eco-friendly membrane technologies used in waterproof hiking jackets?

Yes, sustainable membrane technologies used in waterproof hiking jackets include PFAS-free options like FutureLight from The North Face and polyester-based nano-spun membranes. These reduce environmental impact whilst delivering comparable waterproof and breathable performance for ethical hikers.